At Katalyst Engineering Services, we continually strive to drive innovation by deftly utilizing these resources, changing the issues encountered by various industries and fields with potential solutions.

At Katalyst Engineering Services, we continually strive to drive innovation by deftly utilizing these resources, changing the issues encountered by various industries and fields with potential solutions.

Technical documentation is not a supporting activity in the regulated industries but a requirement in the safe and compliant manufacturing in an industry. It describes product design, construction, testing and maintenance of the products through their lifecycle. Incomplete, ambiguous, or old documentation makes the difference between operational inefficiencies and other effects.

Lack of good documentation has a direct impact on product safety and the enforcement of regulations. Manufacturing research shows that documentation related failures are one of the contributing factors to audit finding and safety deviations.

As more regulatory scrutiny is applied, organisations will be assumed to prove their quality of products, as well as accuracy of documentation. This has transformed technical documentation to an essential control point in compliance manufacturing and not an off-office operation.

Wondering how to align innovation with efficiency in your operations? Our tailored solutions bridge the gap seamlessly

Specifications, work instructions, validation records, change logs and safety manuals are part of technical documentation are used to guide manufacturing and quality. These documents in compliance manufacturing are used as the testimony that the requirements of regulations are known and applied. Poor documentation structure or inconsistent documentation causes discrepancies between approved operation and the operation of an organization.

Analysis of the industry reveals that manufacturers whose documentation is disjointed record more errors when subjected to inspections. The compliance documentation should be accurate, accessible, and traceable to align all the engineering, production, and quality teams. Effective documentation procedures facilitate internal controls as well as the external regulatory demands without impediment to the operations.

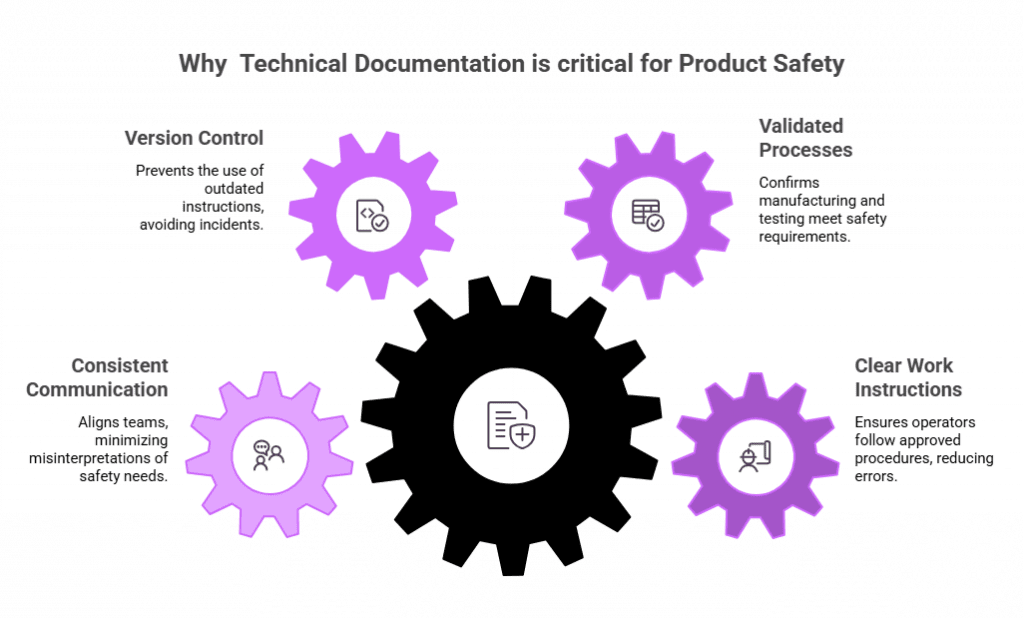

The safety of products is based on clear instructions, validated process and correct communication among the engineering, manufacturing and quality departments. Technical documentation is very important to maintain the consistency of safety requirements during the product lifecycle.

Where documentation is not clear, accurate or subject to version control, the chances of process deviation and unsafe delivery are high. Research shows that organisations that have poor documentation controls have a very high risk of product safety and compliance.

Instead of being a reactive document, documentation is a preventative safety tool that helps to make well-informed and consistent decisions in all stages of operation.

Inadequate technical documentation is a direct threat to compliance manufacturing since it leaves loopholes in what is supposed to be done and what is actually being done. Missing, out of date, or inconsistent records make organisations unable to provide reliable evidence in the process of an audit.

A high number of compliance failures are not due to the defective nature of products, but due to the fact that documentation fails to describe the controlled processes. Clear, traceable and evidence-based compliance documentation showing accountability and process control is expected by the regulators. Absence of documented governance of documentation leads to poor audit readiness, more corrections and delay in operations are inevitable.

Audits depend heavily on compliance documentation to verify that safety and quality systems are truly under control. Regulators assess documentation not just for completeness, but for consistency, traceability, and alignment with actual manufacturing practices. Even strong products can face audit delays when documentation falls short.

| Risk Area | Impact on Operations | Compliance Outcome |

| Product Safety | Increased process errors | Safety deviations |

| Audits | Incomplete evidence | Failed inspections |

| Traceability | Limited visibility | Delayed recalls |

| Costs | Rework and penalties | Revenue loss |

Industry data shows that documentation-related non-compliance can raise operational costs by up to 20%, affecting both profitability and brand credibility.

Improving technical documentation requires standardisation, controlled workflows, and regular reviews. Digital documentation systems improve version control and traceability across departments. Organisations adopting structured documentation practices report faster audit readiness and fewer compliance deviations.

Documentation governance should align with quality management and compliance manufacturing processes. By embedding documentation into daily operations, organisations reduce reliance on manual interventions. Strong documentation frameworks support consistent product safety and long-term regulatory compliance without increasing operational burden.

Katalyst Engineering is a specialist in engineering-based organisations that are regulated manufacturing settings. Having a firm emphasis on processes that are compliance-oriented, Katalyst Engineering is well aware of the effect of technical documentation on product safety and regulatory outcomes.

They focus on organized documentation, traceability and industry standards. They can assist organisations by mitigating the risk of operational lifecycle compliance documentation through tackling documentation issues at the system level.

Enhancing the safety and compliance of products is best achieved through a better documentation practice, which is a key concept promoted by Katalyst Engineering in a regulated manufacturing setup. Organisations can resourcefully deal with regulatory complexity when technical documentation is seen as part of fundamental compliance roles.

Standardization of documentation processes with compliance manufacturing processes creates resilience in the long run. Katalyst Engineering emphasizes the fact that rigorous documentation will minimize safety risks, enhance audit preparedness and narrow down the cost of compliance in the future.

Struggling with designs that don’t scale or processes that slow you down? Katalyst helps you engineer smarter, faster, and better.

Technical documentation defines how products are designed, manufactured, tested, and maintained, ensuring consistency, traceability, and regulatory compliance across operations.

Inaccurate or outdated documentation can lead to process deviations, incorrect handling, and missed safety controls, increasing the risk of defects and safety incidents.

Compliance manufacturing relies on documented evidence to prove adherence to regulatory standards, making accurate and controlled documentation essential for audit readiness.

Compliance documentation helps regulators verify that approved processes are followed consistently, supporting traceability, accountability, and faster audit closure.

Katalyst Engineering focuses on structured, traceable, and governance-driven documentation practices that support product safety and regulatory compliance across manufacturing environments.

Need help understanding our services in depth? Our team of experts will specify everything you require. Tap on the Contact Us button and connect with our team today!