At Katalyst Engineering Services, we continually strive to drive innovation by deftly utilizing these resources, changing the issues encountered by various industries and fields with potential solutions.

At Katalyst Engineering Services, we continually strive to drive innovation by deftly utilizing these resources, changing the issues encountered by various industries and fields with potential solutions.

A dynamic and versatile product is developed, tested, and released through product engineering., The product designs are verified through a multidisciplinary product engineering framework that is optimized from the perspectives of design-to-manufacture, design-for-assembly, and design-for-reliability.

Our mechanical engineering services proficient team of Katalyst engineers works efficiently to develop an innovative product that meets customer experiences, complies with industry measures, and can be produced with innovative design and techniques.

In the machine development process, Mechanical design is a crucial element. Engineers and designers with innovative ideas produce robust design machines that carry out certain tasks while considering usability, robustness, manufacturability, safety, and cost-effectiveness. Conceptualization, detailed design, prototype creation, testing, and final manufacturing are distinct stages of the mechanical design process. Our mechanical engineering services proficient mechanical engineers are key players in mechanical design, bringing their knowledge, skills, and expertise to delivering the product.

Value Engineering (VE) is a systematic, team-based approach that looks at the best ways to carry out a project's activities and provide the desired results to maximize the value of a good or service. We focused on our VA/VE solutions while optimizing through different design structures, quality enhancements through functional analysis of goods and sub-systems, and performance improvement through verifying performance elements and identifying improvement opportunities.

Our reverse-engineering abilities comprehend a product, system, or technology's design, functionality, and underlying mechanics and examine various parameters. We help our clients by examining the product or its segments through its features, behavior, or source code. Under reverse engineering, various benefits are provided by our company, including product understanding, belief in design improvements, modification and customization, and many more.

Our team of professionals believes in innovation, enhancing, and overcoming obstacles more successfully by utilizing a more resonant comprehension of current products and processes.

Mechanical Analysis, also called mechanical engineering services analysis, enables secure, better-designed, and more efficient products. It improves creativity, lowers failure rates, and helps businesses succeed. We assist our clients in achieving the appropriate importance, production, and time-to-market for products. We offer multi-physics service solutions. We are experts in thermal, structural, and multi- dynamics analysis in this field.

Our company possesses specialized knowledge in fluid dynamics and hydraulic systems. Our proficient engineers understand the client's needs and build hydraulic design with optimized and efficient solutions.

Our company complies product localization services, which include benchmarking, value analysis, compliance, comprehensive designing, prototyping and testing, and technical documentation.

CAM (Computer-Aided Manufacturing) and CNC (Computer Numerical Control) programming are important in modern manufacturing processes, particularly in machining, 3D printing, and many more. We optimize the production process to increase efficiency. Using automated machines, CAM/CNC programming enables the creation of actual things, bridging the gap between design and manufacturing.

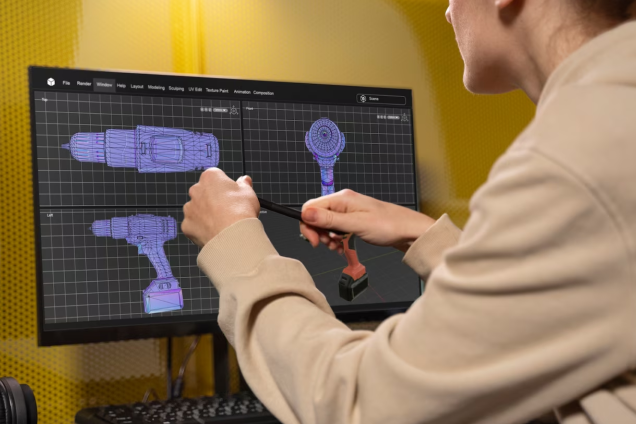

Experience the future of design with our 3D and 2D design comprehensive feature set, which simplifies every step from idea to validation. Our mechanical engineering services used advanced technologies will elevate your product development, embrace design improvements, and give refurbishment projects new life.

Here Are Some Common Questions And Answers From Customers Like You

Mechanical engineering involves everything that moves. And with the world literally getting used to machines, mechanical engineering has become an innate part of our lives. Mechanical engineering services, furthermore, include everything from design to developing every small as well as huge parts of machinery in different sectors. Moreover, the most significant advancements this field has witnessed and will witness include the following-

Advanced technology has strengthened the scope for mechanical engineers to develop and design efficient and strong solutions. Further progress in this field has enhanced the scope to implement creative ideas even more for the engineers. Nevertheless, the future aspect of mechanical engineering services is still dependent on the some industry-enhancing technologies, which include-

Mechanical services providers are known to play a key role in managing environment and pollution related issues. The engineers now a days focus on designing and developing technologies and systems that minimize the emissions from industries including carbon. Their work also covers system design for assisting and minimizing pollution related to transportation.

The professionals work together to develop a sustainable future in a creative manner. It all works according to a planned and multidisciplinary approach that balances social, environmental, and economic structure. The structure can be created with the help of economists, policymakers, and other environmentalists. These engineers take a note of it and work accoridingly in a better and productive manner.

There are multiple skills required while hiring a mechanical engineer in the industry, and they are essential when considering mechanical engineering services. The majorly important skill required in a mechanical engineer is programming and fault detection. Moreover, skills including problem solving and system valuation are also considered valuable.

Need help understanding our services in depth? Our team of experts will specify everything you require. Tap on the Contact Us button and connect with our team today!